ARB Air Lockers®

A relentless commitment to research and design, the use of quality materials, and an uncompromising approach to manufacturing have all contributed to the Air Locker’s success in over 100 countries worldwide. Designed and manufactured in Australia, ARB Air Lockers locking differentials will enhance the traction of your 4×4 in just about any terrain, whether it’s rock, clay, gravel, sand, snow or mud.

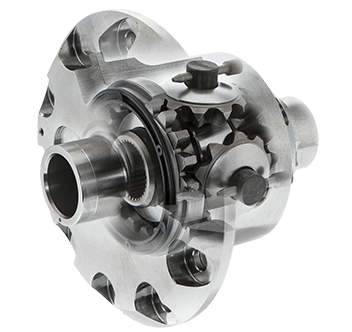

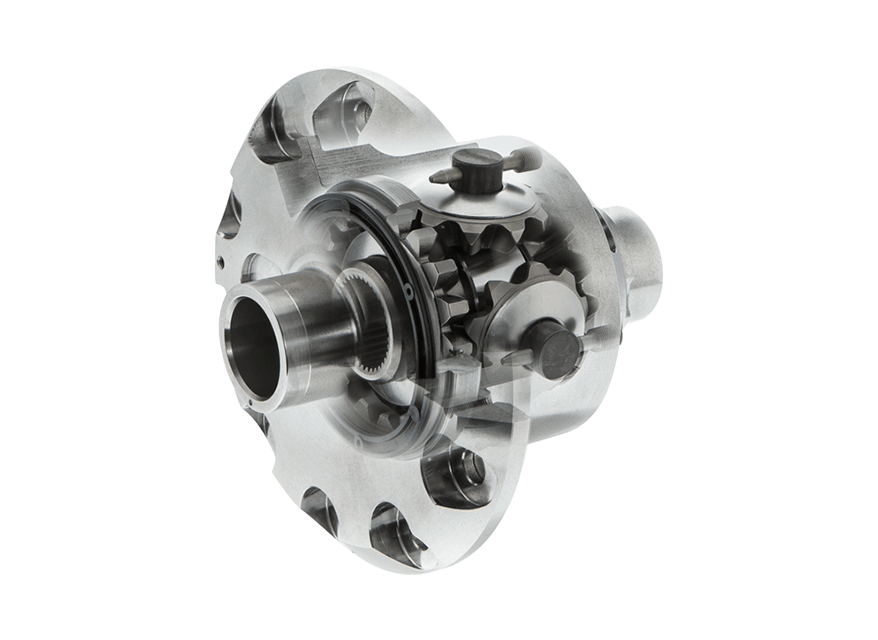

Now with a state-of-the-art two piece design available right across the range, forged gears for the ultimate in strength and durability, and an industry-leading five year warranty, ARB Air Lockers are better built and better backed than ever before. Many people believe that a 4WD and traction go hand in hand… you can’t have one without the other. However, your vehicle’s standard (or open) differential is designed to allow each wheel to turn independently, thus eliminating binding during turns. Off road, this becomes a major burden as engine power will take the path of least resistance, which occurs at the wheels with little or no traction.

Newer vehicles with limited slip differentials may offer some improvement, but more often you’ll find the slipping is not ‘limited’ enough to maintain forward progress. Automatic locking differentials also have their disadvantages. Aside from being noisy when disengaging, they can also upset the on-highway driving characteristics of your vehicle.