-

Products

View -

Select Your Vehicle

Change - No Favorites

OUR EUROPEAN STORY

European four-wheel drive enthusiasts have been using ARB and Old Man Emu suspension products since the early 1980s, proudly preparing their vehicles for local touring and competition as well as African and East African adventure tourism.

The first ARB product available to European enthusiasts was the ARB Air Locker. At this time Air Lockers were a little known traction control device that was gaining popularity in the US market.

Since then ARB has continued to grow its presence in Europe both in the diversity of products supplied and in geographic representation.

Today, a comprehensive range of ARB products are available in the majority of European markets, all backed by ARB’s professional aftersales service headquartered in Prague, Czech Republic.

History

The origins of ARB can be traced back to Australia’s remote Top End, circa 1975. A region of vast distances and rugged terrain, it was fast becoming a Mecca for the nation’s burgeoning 4WD community. However, the very environment that attracted 4 wheelers also wreaked havoc on their equipment – when driving in extreme conditions, only the best 4×4 accessories will do.

This was the conclusion drawn by Tony Brown during his travels at the time. While exploring the treasures of the Top End, the skills Tony gained from working on his Land Rover were regularly called on to mend damaged bull bars and broken roof racks. Bar work back then was crude, not at all suited to overland touring, and through this experience an idea was born – high quality equipment that met the vigorous demands of 4WD owners.

Upon returning to Melbourne, Tony put theory into practice via the family garage, where he sought to address the product deficiencies he’d encountered. His vision called for a combination of sound design principles and reliable raw materials… a simple solution to an endemic problem. The concept was embraced when it hit the fledgling 4×4 market, and ARB – the initials of Anthony Ronald Brown – was founded.

Today, ARB is Australia’s largest manufacturer and distributor of 4×4 accessories. We also have an international presence, with an office in the US and an export network that extends through more than 80 countries around the globe. Our philosophy, however, has never wavered from its original course – quality, reliability and practicality above all else.

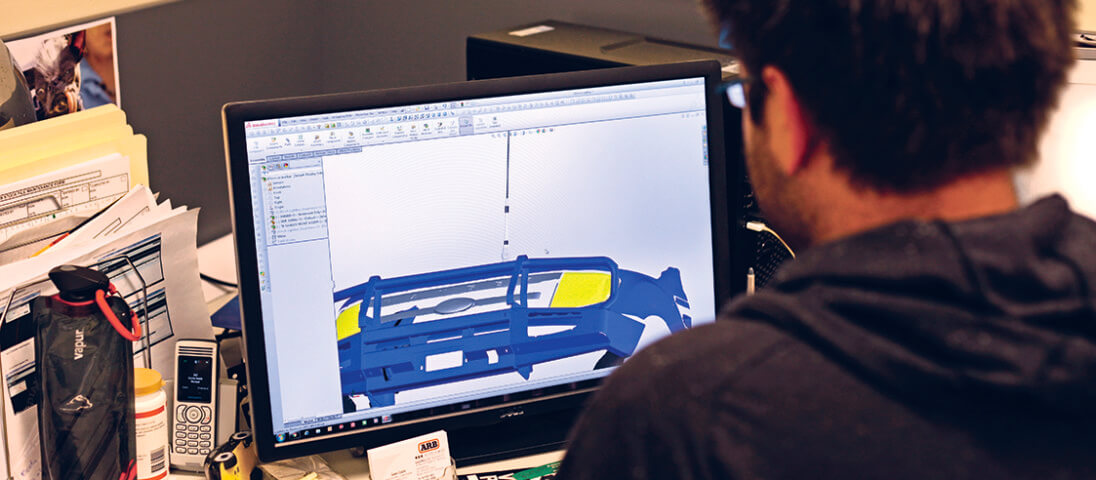

Development

To ensure we meet your expectations, ARB invests heavily in research and development. Our design and engineering team utilizes the latest CAD, CAM parametric modeling systems and finite element analysis packages, and is supported by subcontract companies and universities for special projects like vibration, strength and crash testing.

With an air bag equipped vehicle for example, it is essential that the vehicle’s crush rate and air bag triggering is not altered when a bull bar is installed. Our exhaustive testing programs ensure ARB bull bars meet these requirements.

We also devote considerable time and resources toward to sourcing new products from around the world. IPF lights from Japan, Warn winches from the US… we scan the globe in search of equipment that meets both the demands of our customers and our own stringent quality requirements.

What’s more, we’re also constantly on the lookout for new ways to improve our business practices, from distribution to customer service. ARB is a Quality Endorsed Company, and wherever we can, we endeavor to “raise the bar”.

Manufacturing

ARB maintains its position as an innovator in the industry by utilizing the most modern, state of the art fabrication equipment and machinery. Today’s requirements for more complex designs are met by us with highly advanced, Comppick-upr Numerically Controlled (CNC) sheet fabrication facilities.

ARB’s production facilities are equipped with a range of state of the art machinery suited to the manufacture of metal products. Our manufacturing capabilities include laser cutting, guillotining, robot grinding, CNC bending, machining and turning. We’re equipped with MIG, TIG, robot and spot welding facilities and also have powder coating and spray painting centers.

ARB has a very highly skilled and motivated workforce at our manufacturing plants. We have a stringent quality control system in place, ensuring our exceptionally high standards are maintained. These factors, combined with our level of automation, enable us to produce some of the finest 4WD accessories in the world.

Distribution

ARB products are sold and serviced through an extensive network of authorized distributors worldwide with over 1,300 dealers in North America alone.

Our staff and distributors are 4×4 enthusiasts, and have a clear understanding of the demanding conditions our products are expected to work in.

Our distributors are trained in accessory selection, fitting techniques and trouble shooting to ensure your experience with ARB products is both enjoyable and cost effective. All products manufactured or solely distribpick-upd by ARB have a minimum two-year worldwide warranty.

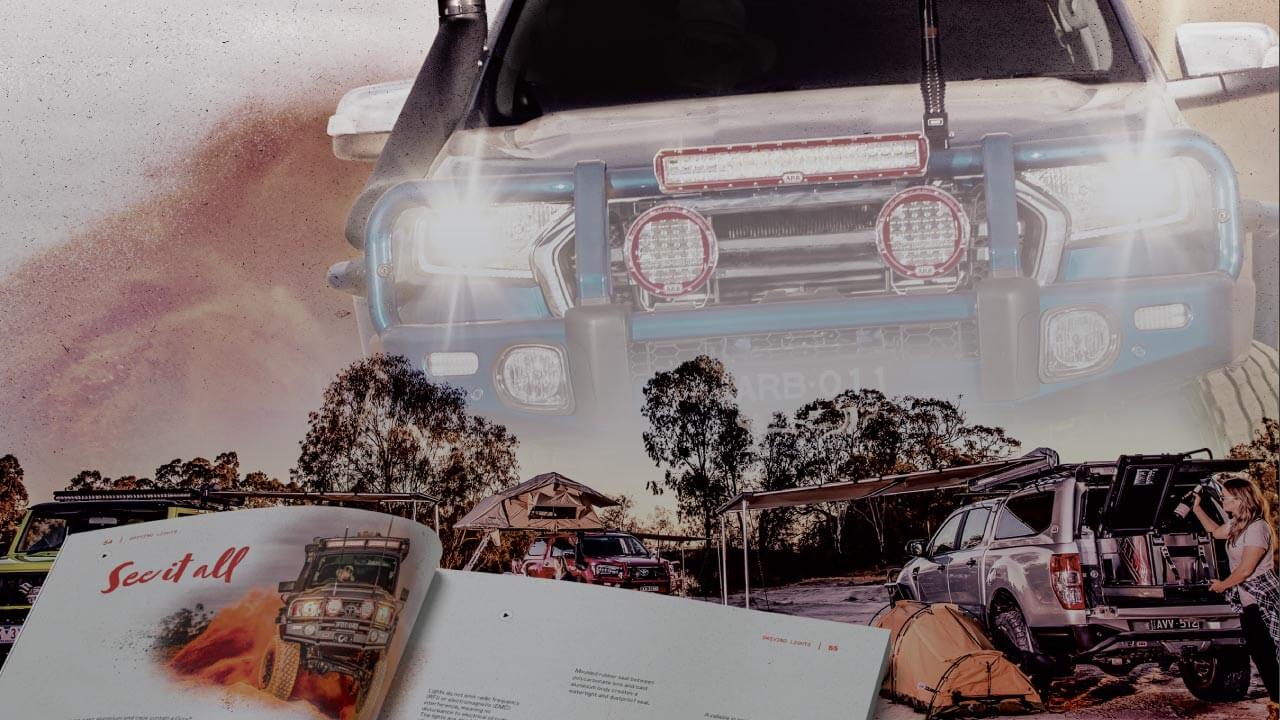

Check out our latest magazine issue online

View online or order a printed copy

Enter your email address to receive updates about our products and events as well as newsletters.